Industrial Pellet Burner - 1 Lakh KCAL

Industrial Pellet Burner - 1 Lakh KCAL Specification

- Condition

- New

- Type

- Natural Circulation

- Size

- 4

- Height

- 2.5 Foot (ft)

- Usage

- Industrial, Power Station

- Structure

- Fire Tube

- Product Type

- Front Pellet Burner

- Weight

- 90 Kilograms (kg)

- Style

- NA

- Color

- Golden Yellow

- Material

- MS

- Width

- 20 Inch (in)

- Length

- 2 Foot (ft)

Industrial Pellet Burner - 1 Lakh KCAL Trade Information

- Minimum Order Quantity

- 1 Number

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 5 Per Day

- Delivery Time

- 3 Days

- Sample Available

- No

- Packaging Details

- As Per Customer required

- Main Domestic Market

- All India, South India, Karnataka, Central India, West India, North India, East India, Gujarat, Kerala, Chhattisgarh, Himachal Pradesh, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Haryana, Rajasthan, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- NA

About Industrial Pellet Burner - 1 Lakh KCAL

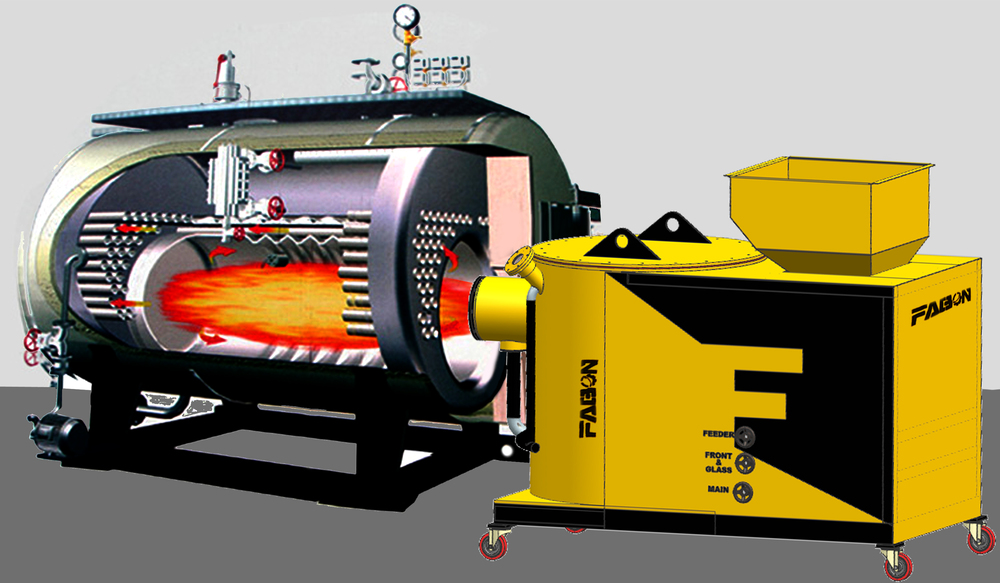

Biomass Front Fire Burner High Efficiency, Low-Cost Heating Solution

Product Description:

The Biomass Front Fire Burner is a powerful and eco-friendly combustion system designed for industrial heating applications. It operates on biomass pellets, delivering clean, efficient, and cost-effective thermal energy for boilers, dryers, ovens, and hot air generators. With its front-fire design, this burner ensures uniform flame distribution, making it ideal for retrofitting or new installations in industries seeking an alternative to diesel, furnace oil, or LPG.

Key Features:

-

Heat Output: Up to 1,00,000 Kcal/hr (customizable to higher capacities)

-

Fuel Type: Biomass Pellets (Agro Waste / Sawdust / Wood Pellets)

-

Combustion Type: Horizontal front-fire flame with controlled ignition

-

Cost-Efficient: Reduces fuel cost by up to 60% compared to fossil fuels

-

Low Emissions: Cleaner burning with minimal smoke and ash

-

Low Maintenance: Robust build with minimal moving parts

-

Automation Ready: Optional PLC-based control for fuel feed and flame control

-

Installation: Easy integration with existing furnace or boiler chamber

-

Safety: Equipped with flame sensor, blower interlock, and overheat protection

Applications:

-

Hot Air Generators

-

Steam Boilers

-

Food Processing Ovens

-

Chemical & Pharma Dryers

-

Rotary Dryers / Flash Dryers

-

Foundry & Melting Furnaces

Advantages:

Eco-Friendly & Renewable Fuel Source

Rapid ROI Less than 1 year

Ideal for 24x7 industrial operations

Works on biomass pellet size 68 mm

Supports automatic or manual feeding options

FABON Engineering Pvt. Ltd. offers complete solutions with burner installation, fuel supply setup, and after-sales support. Customization available for higher capacity models up to 5,00,000 Kcal/hr.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS