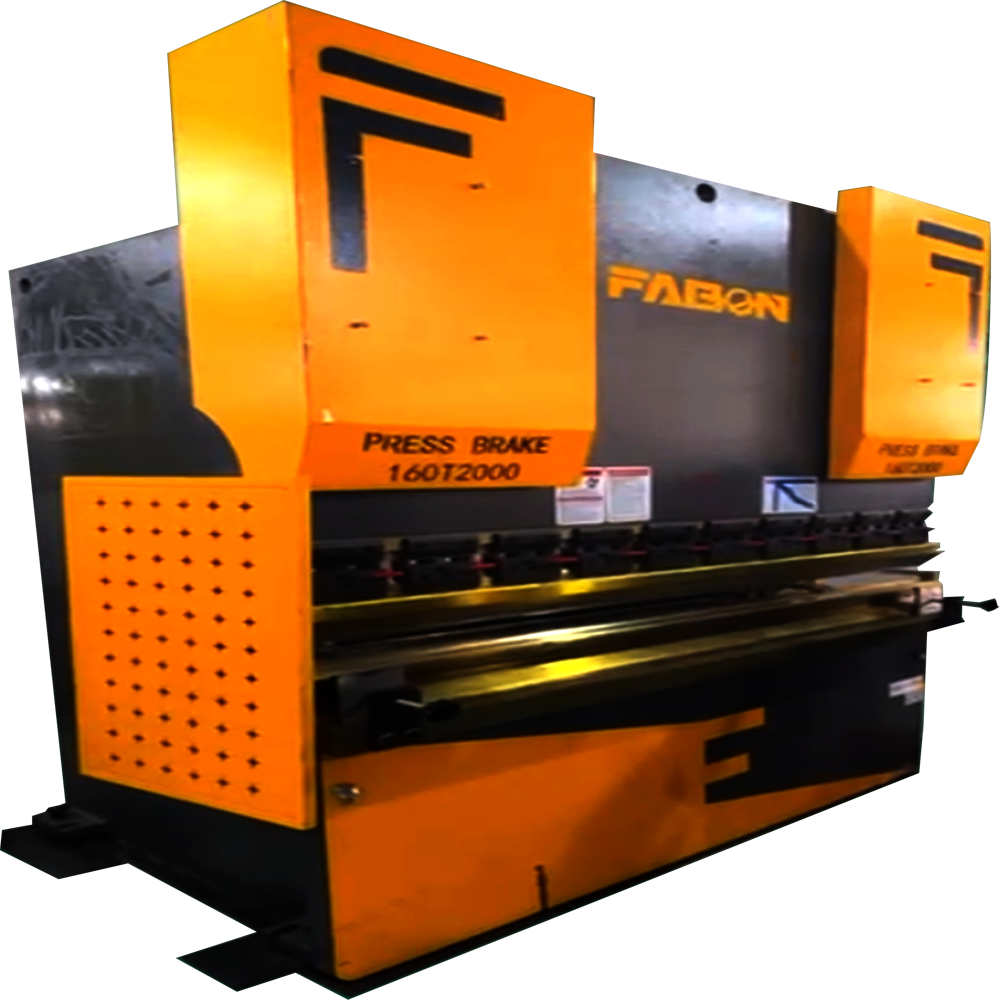

Cnc Pressbreak

Cnc Pressbreak Specification

- Machine Type

- CNC

- Bending Strength

- 200 Tonns

- Bending Angle

- 90

- Output

- 3200mm

- Bending Speed

- 0.3 Second

- Place of Origin

- India

- Dimension (L*W*H)

- 36*72*60 Inch (in)

- Product Type

- Cnc Pressbreak

- Usage

- Industrial

- Color

- Golden Yellow

- Power

- 80 HP Horsepower (HP)

- Automation

- YES

- Raw Material

- All Types of Bending

Cnc Pressbreak Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Week

- Delivery Time

- 1 Week

About Cnc Pressbreak

What is a CNC Press Brake / Bending Machine?

A press brake (or bending machine) is used to bend sheet/plate metal into desired angles/shapes by pressing the sheet between a punch and a die. Wikipedia

A CNC press brake adds computerized control over multiple axes (ram, back-gauge, sometimes crowning, Z axes etc.), enabling repeatable, accurate and complex bending sequences, automatic compensation, and storage of bending programs. ACCURL+2KAAST Machine Tools+2

The machine uses a hydraulic, electric, or hybrid drive system. hindustanhydraulics.com+3ACCURL+3KAAST Machine Tools+3

Advantages include:

-

Better repeatability

-

Faster set-up for multiple bends

-

Reduced operator error

-

Ability to store and recall complex programs

Key Specifications & What to Watch Out For

When you evaluate or design/spec a CNC press brake, these are the main parameters and trade-offs:

| Spec / Feature | Meaning / Why It Matters | Typical Ranges / Examples |

|---|---|---|

| Tonnage / Bending Force | The maximum force the ram can apply to bend material. Too low = cant fully bend or will cause tool / machine damage. | From perhaps 3050 tons (for light sheet) up to hundreds or thousands of tons for thick plates. For example, a 100-ton, 3100 mm machine is common. ACCURL |

| Working / Bending Length | Maximum length of the bend or sheet you can do at once | 0.8 m to 6 m or more (or tandem setups) ACCURL+2marathonengineering.in+2 |

| Stroke / Ram Travel | How far downward the ram can move (depth of bend) | 150400 mm, depending on machine size. E.g. 300 mm stroke in a 100 ton, 3100 mm bed example. ACCURL |

| Open Height / Daylight | Clearance between ram and bed when fully raised | Must accommodate material + tooling thickness. E.g. ~ 550 mm in that 100 ton machine example. ACCURL |

| Throat Depth | Distance from frame face to ram centerline; deeper allows more complex bends inward | e.g. 400 mm in the 100 ton machine example above. ACCURL |

| Axes / CNC Control | Which movements are CNC controlled (Y, Y1/Y2, X, R, Z, crowning) | Many machines have Y1-Y2 + X + optional R or Z axes. Eg. a 135 ton / 3200 mm model has Y1-Y2-X-R with crowning. ACCURL |

| Back Gauge Travel / Speed | How far and how fast the back gauge (which positions the sheet for each bend) moves | Eg. in Hesse AD-S 30320, the back gauge (X axis) speed ~500 mm/s, R axis ~350 mm/s. hesse-maschinen.com |

| Approach / Bending / Return Speeds | Speeds in non-cutting travel, bending motion, and retraction | E.g. Hesse machine: approach rapid ~160 mm/s, work speed ~10 mm/s, retraction ~140 mm/s. hesse-maschinen.com |

| Machine Structure & Rigidity | Frame, welded steel, stress relief, reinforcement | E.g. machines built with welded plates and vibration aging to relieve internal stress. haven-equipment.en.made-in-china.com+1 |

| Crowns / Anti-Deflection | To compensate bending variation along the bed length | Many machines include or allow crowning systems to achieve uniform bend across the length. hesse-maschinen.com+2ACCURL+2 |

| Tooling / Clamping | Punch & die sets, quick change clamps | Many machines support modular tooling, quick clamp systems for fast tooling change. Rajesh Power Press India+2hindustanhydraulics.com+2 |

| Safety & Monitoring | Light curtains, laser guards, presence sensors, interlocks | Modern CNC press brakes often include presence sensing devices (PSDs) to protect the operator. Wikipedia+1 |

| Control Interface & Features | Touchscreen, 2D/3D programming, offline programming, bend sequence optimizer, USB/ethernet | Typical Performance / Use Cases

|

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pressbreak Bending Machine Category

Cnc Bending Machine

Price 1700000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Place of Origin : India

Warranty : Yes

Usage : Industrial

Product Type : Cnc Bending Machine

Send Inquiry

Send Inquiry Send SMS

Send SMS