Biomass Pellet Plant 500 Kg Hour

Biomass Pellet Plant 500 Kg Hour Specification

- Production Capacity

- 500 Kg

- Automation Grade

- Yes

- Motor Power

- 40 Kilowatt (kW)

- Efficiency (%)

- 85%

- Country Of Origin

- India

- Type

- Biomass Pellet Plant

- Material

- Stainless Steel

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Voltage

- 80 Horsepower (HP)

- Power

- 50 Horsepower (HP)

- Weight (kg)

- 500 Kilograms (kg)

- Dimension (L*W*H)

- 20*10*15 Foot (ft)

- Color

- Yellow

- Warranty

- 1 Year

- Capacity

- 500 Kg

- Surface Finish

- Painted

- Power Consumption

- 40 Kilowatt (kW)

Biomass Pellet Plant 500 Kg Hour Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- NAVASHEVA

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Units Per Week

- Delivery Time

- 4 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Available

- Main Export Market(s)

- Asia, Africa

- Main Domestic Market

- Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, Kerala, Lakshadweep, Mizoram, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, West Bengal, All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Meghalaya, Dadra and Nagar Haveli, Telangana

- Certifications

- Available

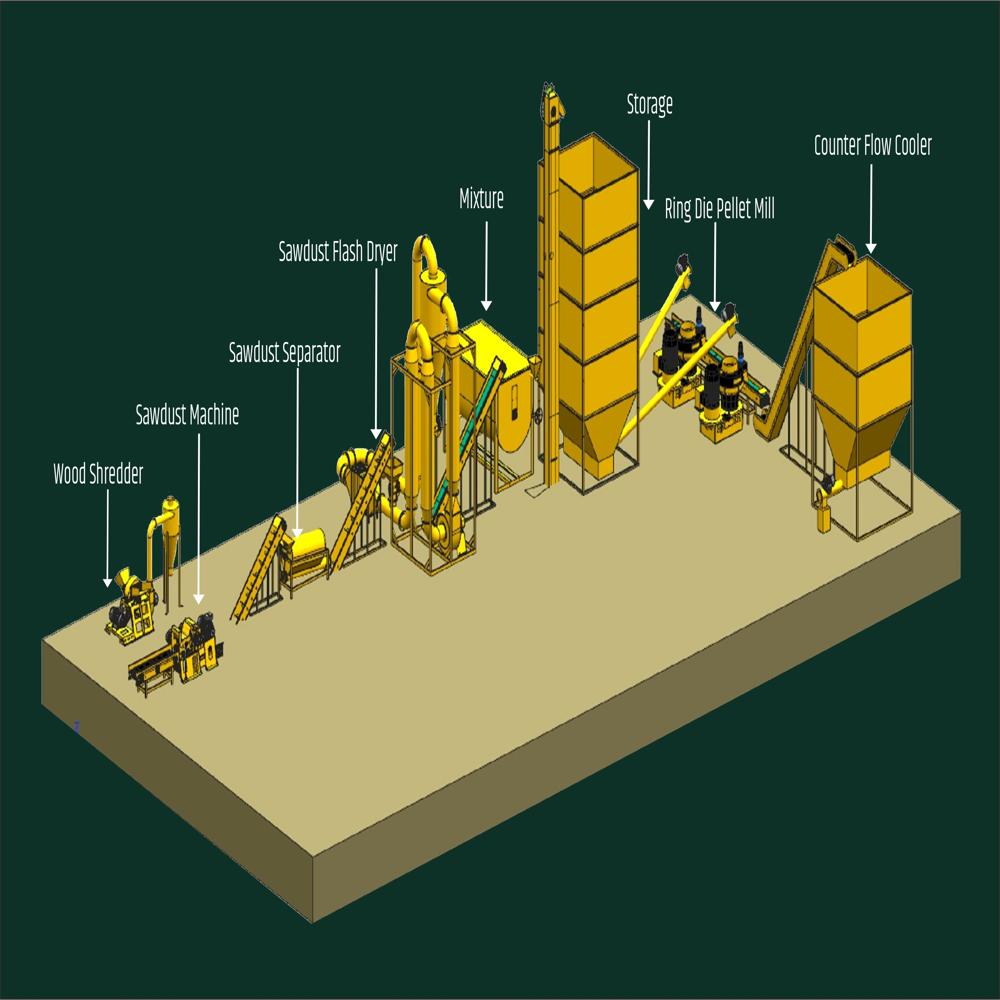

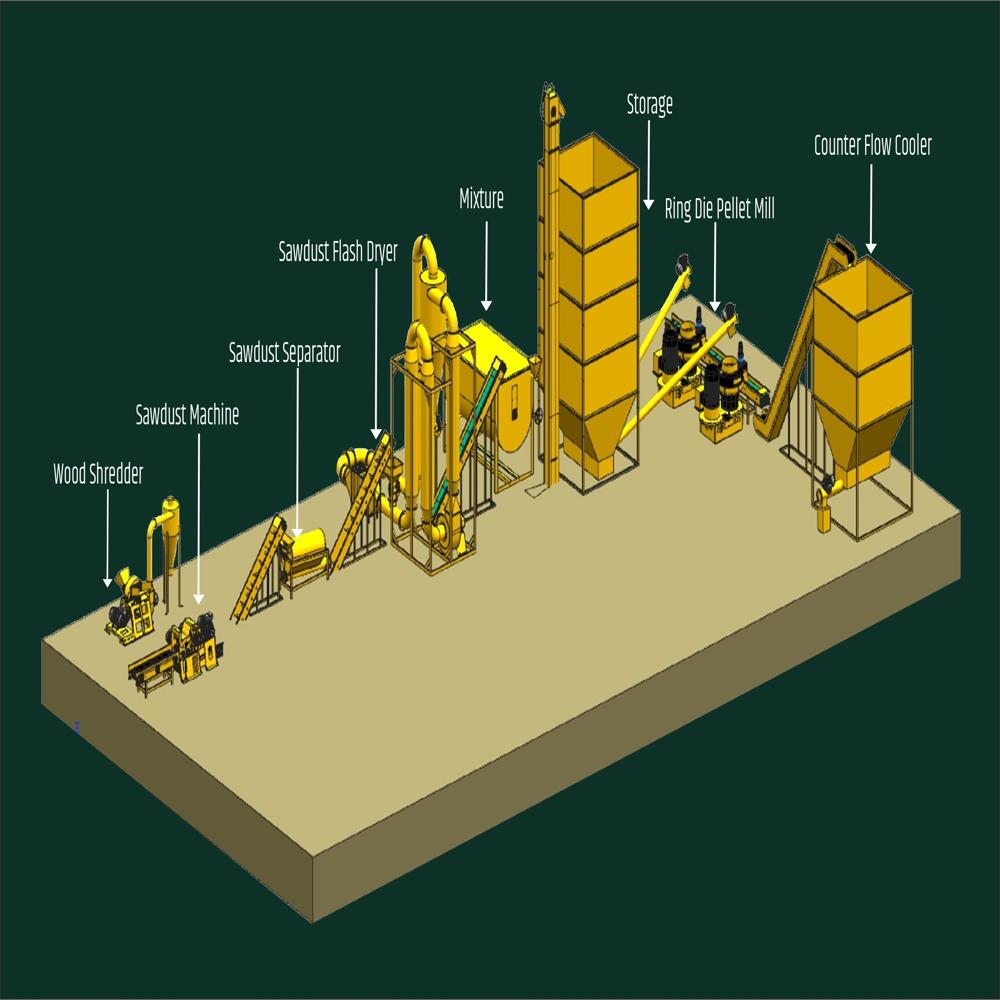

About Biomass Pellet Plant 500 Kg Hour

Biomass Flat Die Pellet Machine 500 kg/hr Production Capacity

The FABON Biomass Flat Die Pellet Machine (500 kg/hour) is a high-performance solution designed for small to medium-scale pellet production. Built with precision engineering and robust materials, this machine efficiently converts agricultural residues, sawdust, rice husk, wood shavings, and other biomass waste into premium-quality biomass pellets.

Key Features

-

Production Capacity: 500 kg/hour continuous output.

-

Design: Compact flat die system for uniform pellet size and durability.

-

Material Compatibility: Works with multiple biomass feedstocks such as sawdust, rice husk, straw, corn stalk, Napier grass, and agri-waste.

-

Energy Efficient: Optimized motor and gearbox design to ensure low power consumption with maximum efficiency.

-

Durable Build: Heavy-duty steel structure with wear-resistant rollers and die for longer service life.

-

Ease of Operation: User-friendly interface, easy maintenance, and low downtime.

-

Applications: Suitable for biomass fuel plants, small industries, poultry/cattle feed manufacturers, and renewable energy projects.

Technical Specifications

-

Model: FABON Flat Die Pellet Machine 500 kg/hr

-

Production Capacity: 500 kg/hour

-

Pellet Size: 6 mm 12 mm (customizable)

-

Motor Power: 4050 HP (depending on raw material)

-

Die Type: Flat Die (hardened alloy steel)

-

Moisture Requirement: Raw material moisture 1015%

-

Application: Biomass pellets for boilers, furnaces, heating systems, and power plants

Advantages

Converts biomass waste into eco-friendly renewable energy fuel

Reduces dependency on fossil fuels and lowers carbon emissions

Compact, low-maintenance design suitable for rural and industrial use

High pellet density for efficient burning and heat generation

FABON Engineering Pvt. Ltd., Nashik (Maharashtra) is a trusted manufacturer of biomass pellet machines with strong after-sales support, spare parts availability, and customized solutions for different biomass projects.

For Enquiry: +91 9370999191 / 9226339191 / 9226719191

Visit: www.fabon.in

Effortless Biomass Pellet Production

The Biomass Pellet Plant 500 Kg Hour offers users a semi-automatic, PLC-controlled system for streamlined pellet production. Its electric drive provides reliable power, while the sturdy steel construction and painted finish ensure durability and longevity. The plants innovative design allows businesses to efficiently process biomass materials while maintaining high output and reduced labor.

Optimized for Efficiency and Safety

Featuring an 85% efficiency rating, the plant guarantees substantial energy savings and operational performance. Its semi-automatic operation, aided by PLC control, promotes safety and precision in every production cycle. The 40 kW motor supports robust pelletizing, and the systems user-friendly interface makes it accessible for operators with varying skill levels.

FAQs of Biomass Pellet Plant 500 Kg Hour:

Q: How does the Biomass Pellet Plant 500 Kg Hour operate?

A: This plant utilizes a semi-automatic process, powered by a 40 kW electric motor. Operators feed biomass into the hopper, and the material undergoes pelletization through a PLC-controlled system, ensuring consistent quality and efficient production at a rate of 500 kg per hour.Q: What materials can be used in this pellet plant?

A: The plant can process a variety of biomass materials such as agricultural residues, sawdust, and wood chips. Its build with stainless steel ensures compatibility with different feedstocks and delivers durable performance.Q: When is regular maintenance recommended for this pellet plant?

A: It is advisable to perform routine maintenance checks every six months, or according to usage levels, to ensure optimal efficiency and prevent downtime. The manufacturers manual provides detailed maintenance guidelines for parts and lubrication.Q: Where can the Biomass Pellet Plant be installed?

A: With a compact footprint of 20 x 10 x 15 feet, the plant can be installed at industrial sites, agricultural processing facilities, or dedicated biomass pellet manufacturing units. It requires access to an 80 HP electric supply for optimal operation.Q: What is the process involved in making biomass pellets with this plant?

A: Raw biomass is loaded into the hopper, where it is compressed and extruded through dies under heat and pressure, forming dense, uniform pellets. The PLC control ensures precise operation throughout the process.Q: How is the plant beneficial for businesses?

A: Businesses using this pellet plant benefit from high production rates, energy efficiency, and reduced manual labor. The semi-automatic system maximizes output while lowering operational costs, making it ideal for expanding pellet production capacities.Q: What kind of warranty and after-sales support is provided?

A: The Biomass Pellet Plant comes with a 1-year warranty, covering manufacturing defects and parts replacement. As an exporter, manufacturer, and supplier based in India, the company provides installation assistance and continuous technical support.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Biomass Pellet Machine Category

BIOMASS PELLET MAKING MACHINE

Price 1850000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Efficiency (%) : 90

Country Of Origin : INDIA

Plastic Processed : NO

Voltage : 440 Volt (v)

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free