Biomass Pellet Plant 2000 Kg Hour

Biomass Pellet Plant 2000 Kg Hour Specification

- Efficiency (%)

- 85%

- Model No

- 560

- Production Capacity

- 2000 Kg

- Usage & Applications

- To Manufactured Biomass Pellets

- Country Of Origin

- Indian

- Type

- Biomass Pellet Plant

- Material

- Stainless Steel

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Voltage

- 240 Horsepower (HP)

- Power

- 132 Watt (w)

- Weight (kg)

- 5 Long Ton

- Dimension (L*W*H)

- 3*4*4 Foot (ft)

- Color

- Golden Yellow

- Warranty

- 1 year

- Capacity

- 2000 Kg

- Features

- Smart HMI Control

- Machine Type

- Yulong Pellet Mill

- Power Consumption

- 132 Kilowatt (kW)

- Surface Finish

- Painted

Biomass Pellet Plant 2000 Kg Hour Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Week

- Delivery Time

- 6 Week

About Biomass Pellet Plant 2000 Kg Hour

FABON 2 TPH Biomass Pellet Plant

High-Efficiency, Multi-Feedstock, Make-in-India Solution

1) Product Overview

A fully-integrated, industrial pellet line engineered for continuous 2022 hrs/day operation. Handles Napier grass, rice husk, sawdust, agro-waste blends and more. Designed for low OPEX, high uptime, safe operation, and clean emissions.

Rated Output: 2,000 kg/hour (5% on feedstock & moisture)

Operation: Continuous, PLC-HMI controlled (auto + manual)

End Use: Industrial heating/boilers, hot-air generators, furnaces, gasifiers, CHP

2) Feedstock Window (Typical)

-

Napier grass (chopped, dewatered), paddy straw, corn cobs, soybean/cotton husk

-

Woody biomass: sawdust, wood chips (size-reduced), veneer waste

-

Agri residues: rice husk, groundnut shells, mustard husk, press-mud blends

-

Target input moisture:

-

Dryer inlet: 3055% (Napier/green biomass)

-

Pellet mill inlet: 1012% (optimal 11%)

-

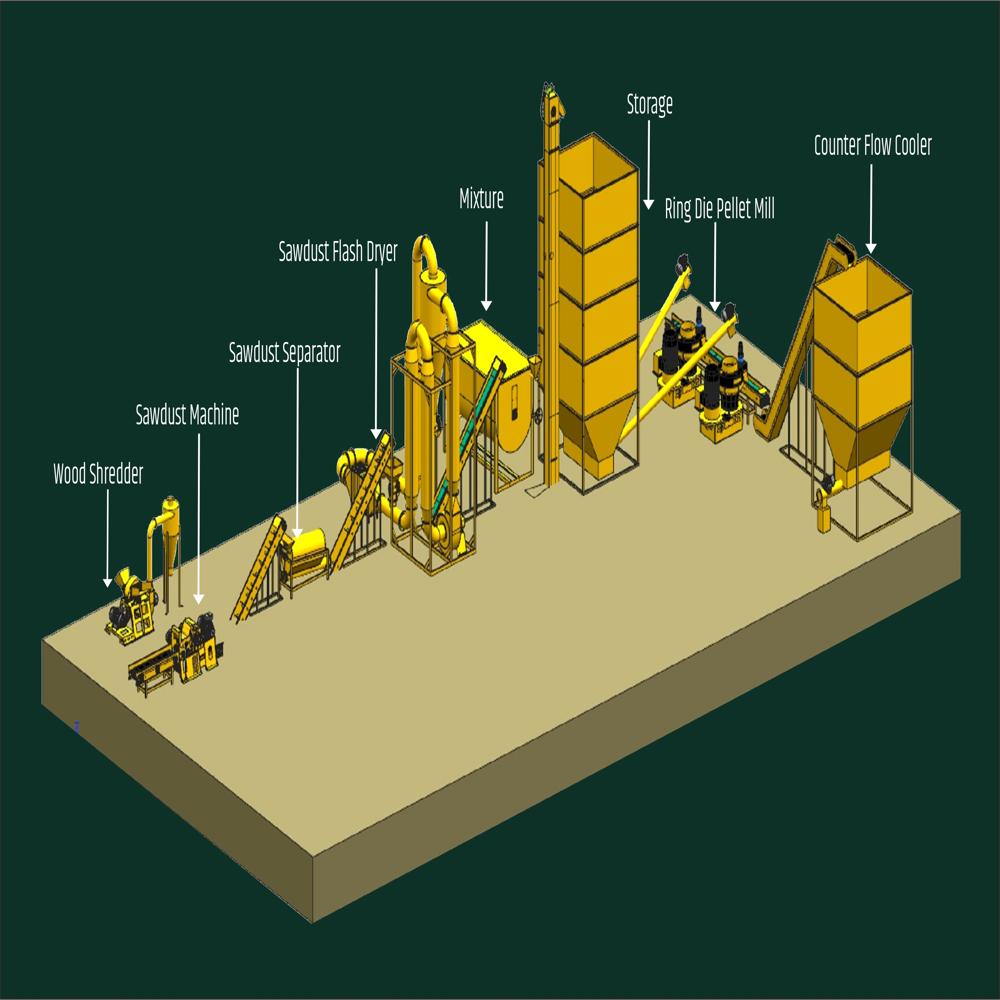

3) Process Flow (Block Diagram)

Raw Material Receiving Size Reduction (Crushing/Chipping) Dewatering (for wet grass) Hot-air Drying Screening/De-stoning Hammer Milling Mixing/Conditioning Pelletizing (Ring-Die) Cooling Screening Weighing & Bagging Finished Goods

4) Major Equipment & Specs (FABON Standard)

-

Intake & Pre-Processing

-

Truck unloading hopper with grille & level sensors

-

Belt/chain conveyors, bucket elevators (dust-tight)

-

Magnetic separator + de-stoner

-

-

Size Reduction

-

Twin-shaft grass crusher/chipper (Napier/straw) 58 TPH loose, 3755 kW

-

Hammer Mill (heavy-duty) 2.53 TPH @6 mm screen, 5575 kW, wear-lined

-

-

Dewatering (for Napier/green biomass)

-

Twin-screw dewatering press; 3035% moisture reduction typical

-

SS contact parts; juice outlet for ferti-irrigation/ethanol use

-

-

Drying System (fuel: biomass burner)

-

FABON Hot-Air Rotary/Flash Dryer sized for 2 TPH pellet line

-

Inlet moisture 3055% outlet 812%

-

Biomass Pellet Burner 1012 Lakh kcal/h with auto ignition, flame safeguard, cyclone & hot-gas ducting

-

Primary cyclone + ID fan + wet scrubber/bag filter (as ordered)

-

-

Mixing & Conditioning

-

Vertical/Batch mixer 23 m, binder/water dosing, moisture probe

-

Steam-free thermal conditioning (optional steam kit on request)

-

-

Pelletizing Section (Heart of the Line)

-

Ring-Die Pellet Mill(s): 22.5 TPH nameplate; 110132 kW main drive

-

Force feeder + conditioner, auto-lube (pump + manifold), main shaft temp & vibration monitoring

-

Die: 6/8 mm (others on request), high-chrome steel

-

Pellet Cooler (counter-flow) 34 TPH with rotary/slide valve, level sensors

-

Final Screener (overs return) + fines recycle

-

-

Storage, Packing & Dispatch

-

Intermediate bins with level indication

-

Belt/auger conveyors to Scale + Stitcher (1050 kg bags)

-

Optional jumbo bag (FIBC) station

-

-

Controls & Electricals

-

PLC-HMI panel (Siemens/L&T/Delta as specified), MCC with VFDs/soft starters

-

Interlocks: over-temp, choke, bearing temp, vibration, bag filter P, burner flame fail, ID/FD fans, and emergency stops

-

Field instrumentation: thermocouples, moisture sensors, DP gauges, current/kw logging

-

5) Performance Guarantees (Typical)

-

Pellet Output: 2,000 kg/h continuous on specified mix and moisture

-

Pellet Quality: 68 mm dia; bulk density 600750 kg/m; durability (PDI) 95% (with correct recipe & prep)

-

Specific Power (Pelletizing): 7095 kWh/ton (feedstock dependent)

-

Final Moisture: 812% at cooler discharge

6) Utilities & Infrastructure (Indicative)

-

Connected Electrical Load: ~465 HP (347 kW) process + margin to ~500 HP incomer for auxiliaries/future; average running 220260 kW depending on mix

-

Power Supply: 415 V, 3-phase, 50 Hz; recommended 630750 kVA transformer, APFC for PF0.95

-

Compressed Air: 67 bar, 12 m/min (lube system, bag filter purging, actuators)

-

Water: 12 m/day (scrubberif wet type; domestic)

-

Shed Area: 12,00015,000 sq ft clear span; min. eave height 810 m (dryer & cooler headroom)

-

FG/WIP Storage: Raw 200400 m; Finished 150250 m (depends on dispatch cycle)

-

Manpower/Shift: 812 (operator 23, helper 35, electrician 1, fitter 1, QC 1)

7) Emissions & Safety

-

Primary cyclone + bag filter/wet scrubber meet local norms (stack 150 mg/Nm PM with correct sizing).

-

Spark arrestors, rotary valves, explosion vents (where applicable), earth bonding.

-

Interlocked burner safeguards; fire extinguishers & hydrant points as per layout.

-

CE/EN ISO 12100 style risk reduction on request (risk assessment dossier extra).

8) Quality Control

-

Incoming moisture & size check; magnet/de-stoner logs

-

In-process moisture (post-dryer, pre-pellet)

-

Pellet PDI, fines %, bulk density, ash % (as per customer SOP)

-

Batch traceability through HMI lots & daily production report

9) Scope of Supply (FABON Standard)

Included

-

All mechanical equipment listed in 4 with base frames, guards, standard fasteners

-

Burners, fans, cyclones, ducting, supports, dampers (as per design)

-

Electrical MCC/PLC-HMI, cabling within plant limits, control wiring

-

Commissioning spares (consumables set), tools kit, O&M manuals, training

Optional/Upgrades

-

Wet scrubber vs. bag filter; heat-recovery (HX)

-

Fire detection & suppression (UL/FM)

-

Steam conditioning kit; binder dosing skid

-

FIBC station; palletizer; inline metal detector (post-pellet)

-

Remote monitoring (IIoT) & energy meters panel

-

SS contact parts (food/animal feed applications)

Exclusions (unless specified)

-

Civil works, foundations, structural platforms, sheds

-

Inbound raw-material handling vehicles, weighbridge

-

HT yard, transformer, DG set, statutory fees, utilities beyond battery limits

10) Project Deliverables & Timeline (Typical)

-

Engineering: GA layout, P&ID, cable tray route, load list, foundation loads

-

Documentation: O&M, PM checklists, risk assessment (if ordered), test certificates

-

Erection & Commissioning: Supervisory or turnkey as per PO

-

Timeline: 1014 weeks manufacturing; 23 weeks erection & dry/wet trials (subject to scope & approvals)

11) Maintenance & Spares

-

Preventive schedule: daily/weekly/monthly (greasing, screens, die/roller inspection)

-

Critical spares pack (recommended): ring-die (2 sets), press rollers (2 sets), HM screens (3 sets), bearings (critical), belts, lube kit, thermocouples, V-belt sets, bag filter bags (10%), sensor pack.

-

AMC available (quarterly health checks / uptime SLAs).

12) Commercial Notes (Indicative)

-

Energy Cost: 70110 kWh/ton (end-to-end), feedstock-dependent

-

Binder: 02% typical (material dependent)

-

OPEX Levers: moisture control, correct screen selection, die L/D, operator skill

-

Warranty: 12 months from commissioning or 15 months from dispatch (whichever earlier) against manufacturing defects.

13) What Makes FABON Different

-

Proven Napier-to-Pellet expertise (dewatering + drying balance)

-

Rugged hammer mill & pellet press package for abrasive agri residues

-

Burner + dryer matched in-house for best SFC & stable outlet moisture

-

Indian spares availability, rapid service, operator training with SOPs

14) Tech Summary (One-Glance)

-

Capacity: 2 TPH finished pellets

-

Die Size: 6/8 mm standard (others on request)

-

Final Moisture: 812%

-

Connected Load: ~500 HP (373 kW) incomer; avg run 220260 kW

-

Area: 12k15k sq ft shed

-

Air Pollution Control: Cyclone + bag filter / wet scrubber

-

Controls: PLC-HMI, interlocks, auto-lube, trend logging

15) SEO Pack (for your website/blog)

-

Title: FABON 2 TPH Biomass Pellet Plant High-Efficiency Napier/Agri-Waste to Pellets

-

Slug:

fabon-2-tph-biomass-pellet-plant -

Meta Description (160 chars):

High-efficiency 2 TPH biomass pellet plant by FABON. Handles Napier, rice husk, sawdust. Low OPEX, PLC-HMI, clean emissions. Make-in-India turnkey line. -

Focus Keywords: 2 TPH biomass pellet plant, Napier grass pellets, rice husk pellets, pelletizing line India, FABON pellet machine, biomass dryer, pellet burner

-

Hashtags (social): #FABONEngineering #BiomassPellets #2TPH #NapierGrass #RiceHusk #RenewableEnergy #PelletPlant #MakeInIndia #GreenEnergy

Efficient Semi-Automatic Pellet Production

Combining smart PLC control and HMI interfaces, the Biomass Pellet Plant delivers reliable, user-friendly operation. Its semi-automatic design enhances safety and minimizes manual work, boosting overall productivity. Precision engineering ensures uniform pellet sizes, making it ideal for large-scale production and commercial distribution.

Robust and Durable Construction

Constructed from high-grade stainless steel and steel, this plant guarantees long-term durability, even under continuous operation. The painted finish protects against corrosion, while its compact footprint means it can be installed in space-constrained facilities without compromising output.

Advanced Technology for Quality Pellets

Utilizing computerized controls and efficient electric drive, the plant maintains consistent pellet quality with minimal power consumption. The Yulong Pellet Mills Model 560 technology maximizes energy efficiency (85%), reducing operating costs while meeting diverse biomass pellet demands.

FAQs of Biomass Pellet Plant 2000 Kg Hour:

Q: How does the Biomass Pellet Plant 2000 Kg/Hour operate?

A: The plant works by processing raw biomass materials through a computerized Yulong Pellet Mill, using smart PLC and HMI controls. The semi-automatic system manages feeding, compression, and extrusion to produce uniform biomass pellets with minimal human intervention.Q: What materials can be used with this pellet plant?

A: You can use various raw biomass materials such as wood chips, sawdust, straw, and agricultural residues. The stainless steel and steel construction makes it compatible with a wide range of feedstocks suited for pellet fuel and industrial use.Q: When is the best scenario to use this biomass pellet plant?

A: This plant is ideal for medium to large-scale manufacturers needing consistent pellet output of 2000 Kg per hour. Its particularly suited for businesses seeking sustainable fuel alternatives and those involved in large-scale biomass pellet export or supply.Q: Where is the Biomass Pellet Plant manufactured and supplied from?

A: This specific model is proudly manufactured, supplied, and exported from India. Its compact size allows for use in a variety of industrial settings domestically and internationally.Q: What are the main benefits of using this semi-automatic pellet plant?

A: Key advantages include high production efficiency (85%), reduced labor requirements due to semi-automation, consistent pellet quality ensured by computerized controls, and robust construction for longevity and reliability in demanding environments.Q: What is included in the warranty and support for the pellet plant?

A: The product includes a one-year warranty covering manufacturing defects. As a supplier and exporter, the manufacturer provides technical support and guidance for installation and operation throughout the warranty period.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Biomass Pellet Plant Category

Biomass Pellet Plant 1000 Kg Hour

Price 2320000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Machine Type : Yulong Pellet Mill

Technology : SemiAutomatic

Drive Type : Electric

Capacity : 2000 Kg

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free